Brakes are the essential part of any machinery, from a two-wheeler to heavy dump trucks. With ever-evolving technologies, brakes have revolutionized. We go for the most efficient and safe breaks, from simple wooden structures to the latest copper water cooled brakes.

Traditionally, disc brakes were used and were a great invention of their time. But, they had a significant flaw in them. Disc brakes were prone to experience high temperatures, which eventually made them less efficient. To counter this problem, the use of fluids such as water was deemed to be successful. Let us evaluate why these water-cooled brakes are the best in the business.

What is a water-cooled brake system?

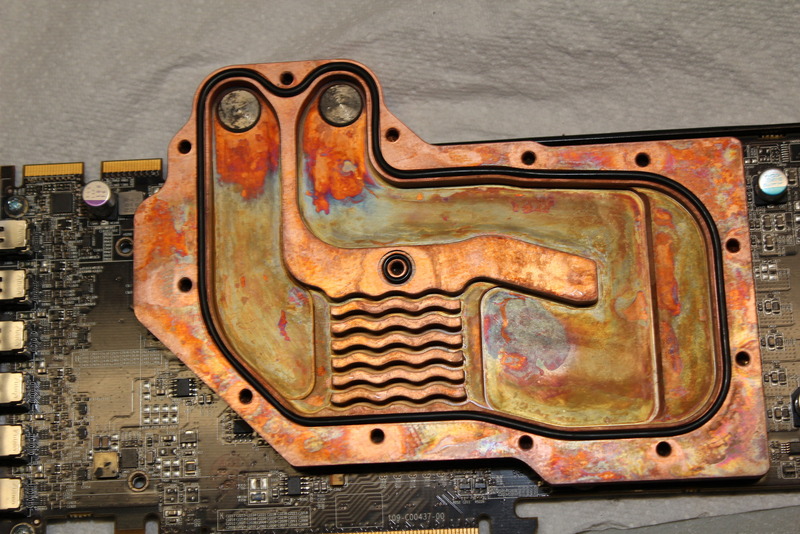

Copper water cooled brakes consist of a disk made of a central and stationary copper cooling plate attached with an internal chamber for circulation of water coolant. This precise design enables an endless flow of liquid without any significant resistance. The brake has a series of cast iron sectors, which are mounted on the opposite side of the disc plate. This reduces the friction from discs on the shaft. This system is efficient due to a thermal insulating layer between the cooling plate and iron cast sector. The insulating layers can be of many types, such as gaps in thin air.

While in use, the iron sectors have enough thermal capacity that enables them to retain the excessive heat produced. This heat is then transmitted to the coolant at a rate that is determined by the conductance of the thermally insulated layers. Thus, the extra heat is absorbed efficiently by the whole system.

This mechanism makes water-cooled brakes an essential part of vehicles and a variety of applications such as heavy machinery and armoured military vehicles.

Advantages of water-cooled brakes

The most commonly used disc braking system uses dry fiction disc brakes that are air-cooled externally. Though this type of braking system has proved successful in small machinery, a significant flaw is experienced while operating heavy machinery. Dry friction disk brake doesn’t allow enough passage for the liquid to pass, resulting in reduced performance and energy loss.

Copper water cooled brakes have the upper hand over dry friction disk brakes. Water-cooled brakes supply the coolant while the breaks are operating but with an increased rate of cooling. Another advantage of water-cooled brakes is a constant flow of water, enabling high heat dissipation. Due to the versatile nature of water coolant, the overheated discs are also cooled down within seconds to reduce machinery power loss.

Thus, these advantages, combined with brakes’ firm structure, make water-cooled breaks more effective than traditional discs breaks. The metal used in such a braking system has high thermal conductivity to inhibit excessive surface temperatures.

Conclusion:

Brake fade is a primary concern for people operating heavy machinery. So, for industrial use, water-cooled brakes are a must as you can’t afford to have your equipment breaking down due to excessive heat or components getting worn-out. Moreover, water-cooled braking systems come with corrosion-free metal surfaces to avoid any further treatment and care.

Stay connected